Inert material purification and non-ferrous metal valorization.

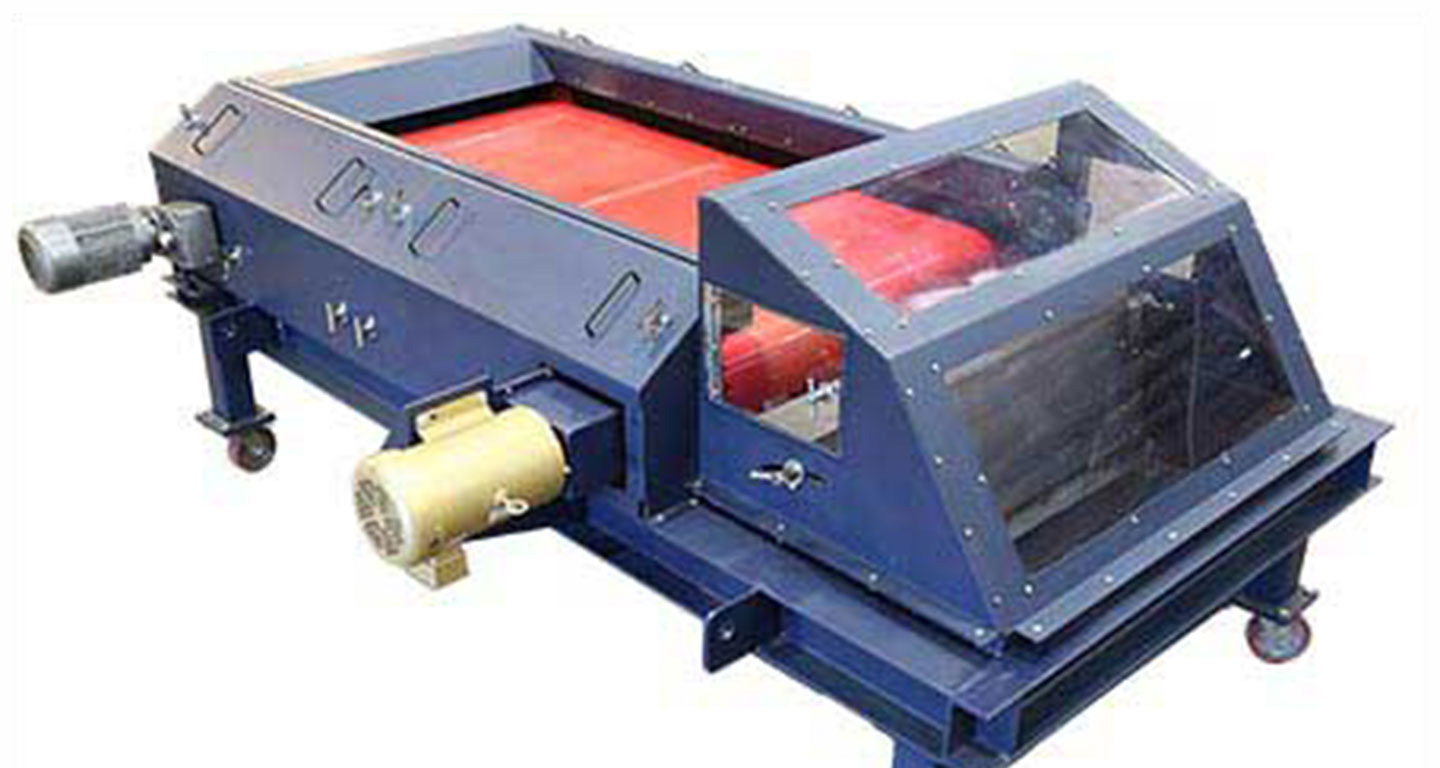

An eddy current separator is a sorting machine used in the recycling of waste. This machine separates non-ferrous metals (aluminum, zinc, copper, etc.) other inert products, including ferromagnetic material.

The principle of the eddy current separator consists of a conductive mass subjected to a variable magnetic field that induces the appearance of a magnetic field within this mass. This induced field allows the magnetic separation of non-ferromagnetic metal elements.

The separator (conveyor head pulley) then generates a repulsive magnetic field that propels nonferrous metals to the output of conveyor. While ordinary waste falls by gravity on a transfer conveyor or in a container, aluminum and non-ferromagnetic metal elements are raised and projected ahead to another conveyor or container. The incoming flow of mixed material to be processed is separated into two flows, one of which is for non-ferrous metals.

Our eddy current separators are equipped with protective guards for moving parts and meet CNESST security standards.

Let Vibrotech help to optimize your separation processes and recuperation efforts.